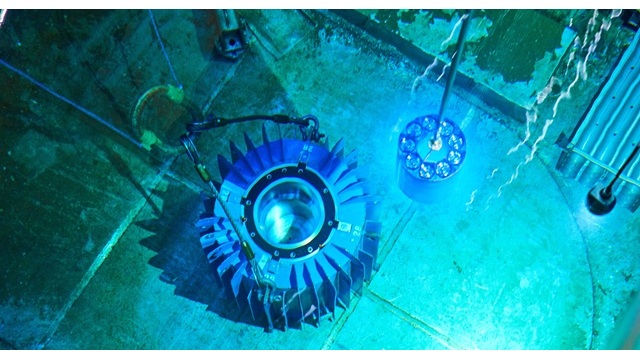

Nuclear Material Handling Systems

Technical Challenge

Designed radiation-shielded handling systems for radioactive materials requiring:

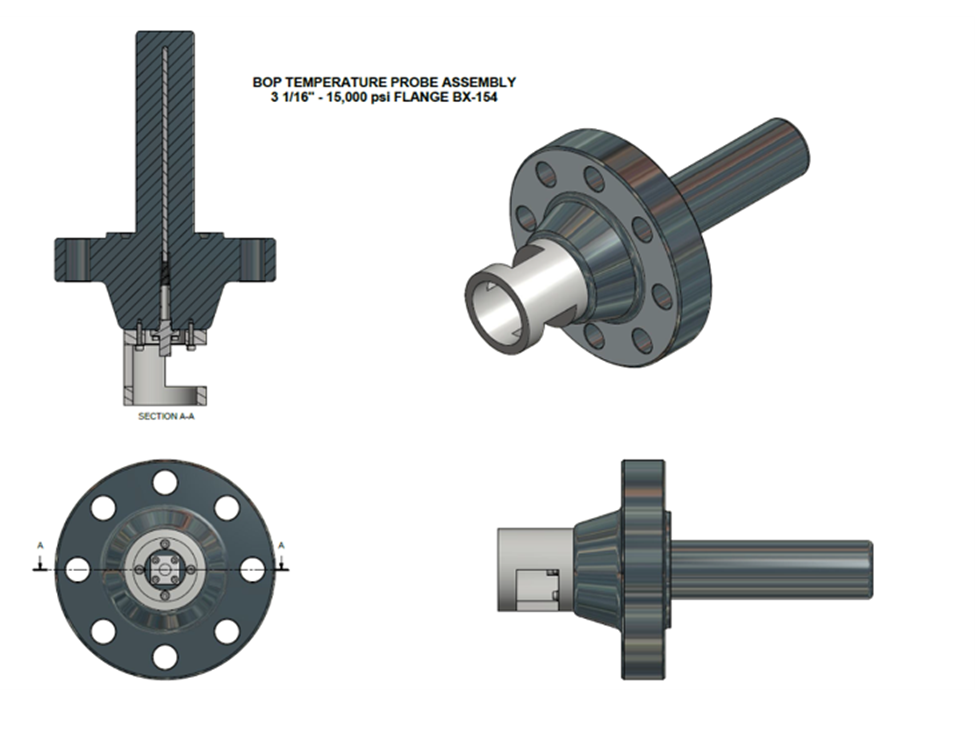

- ±0.005" machining tolerances on critical interfaces

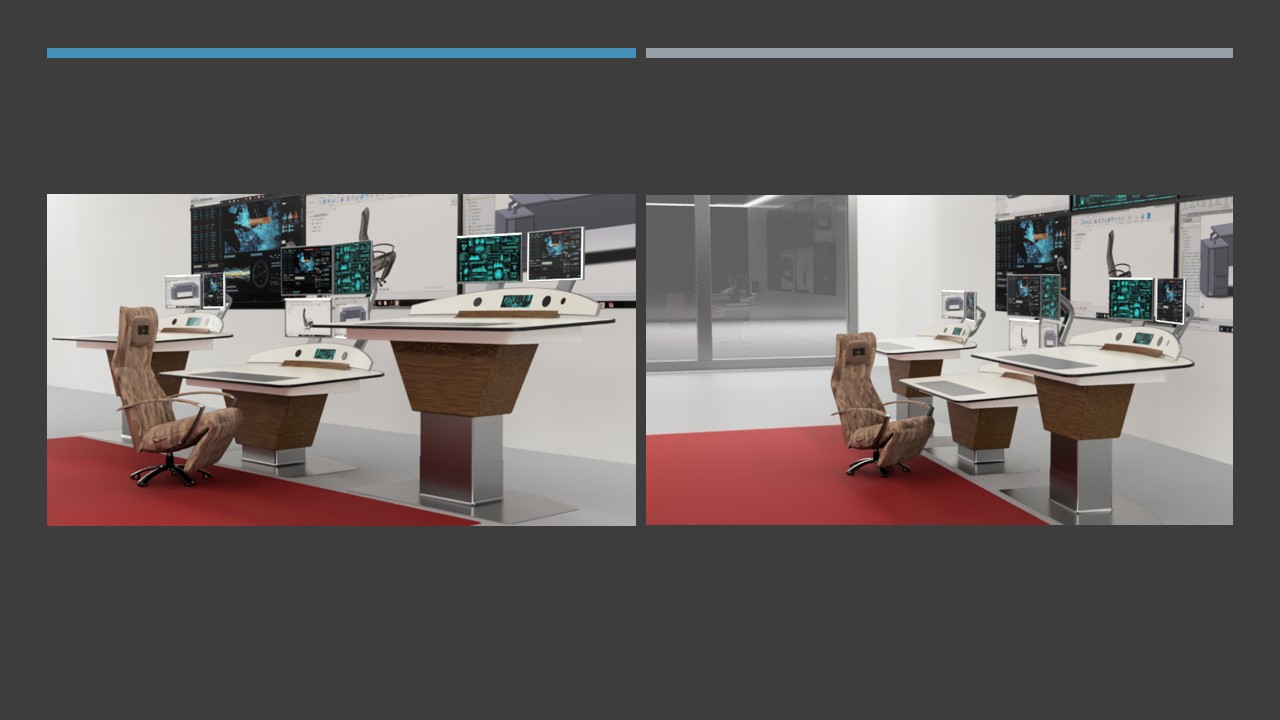

- Remote maintenance capability in high-radiation zones

- Seismic qualification to IEEE 344 standards

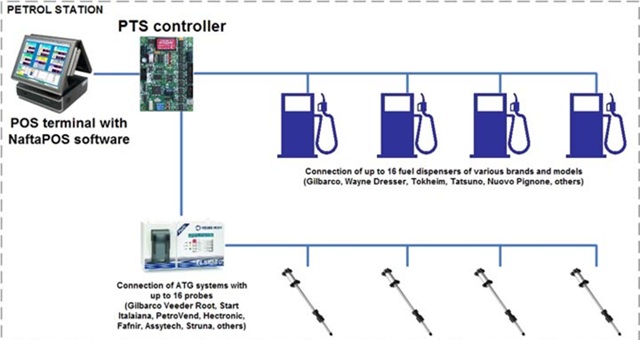

Design Solution

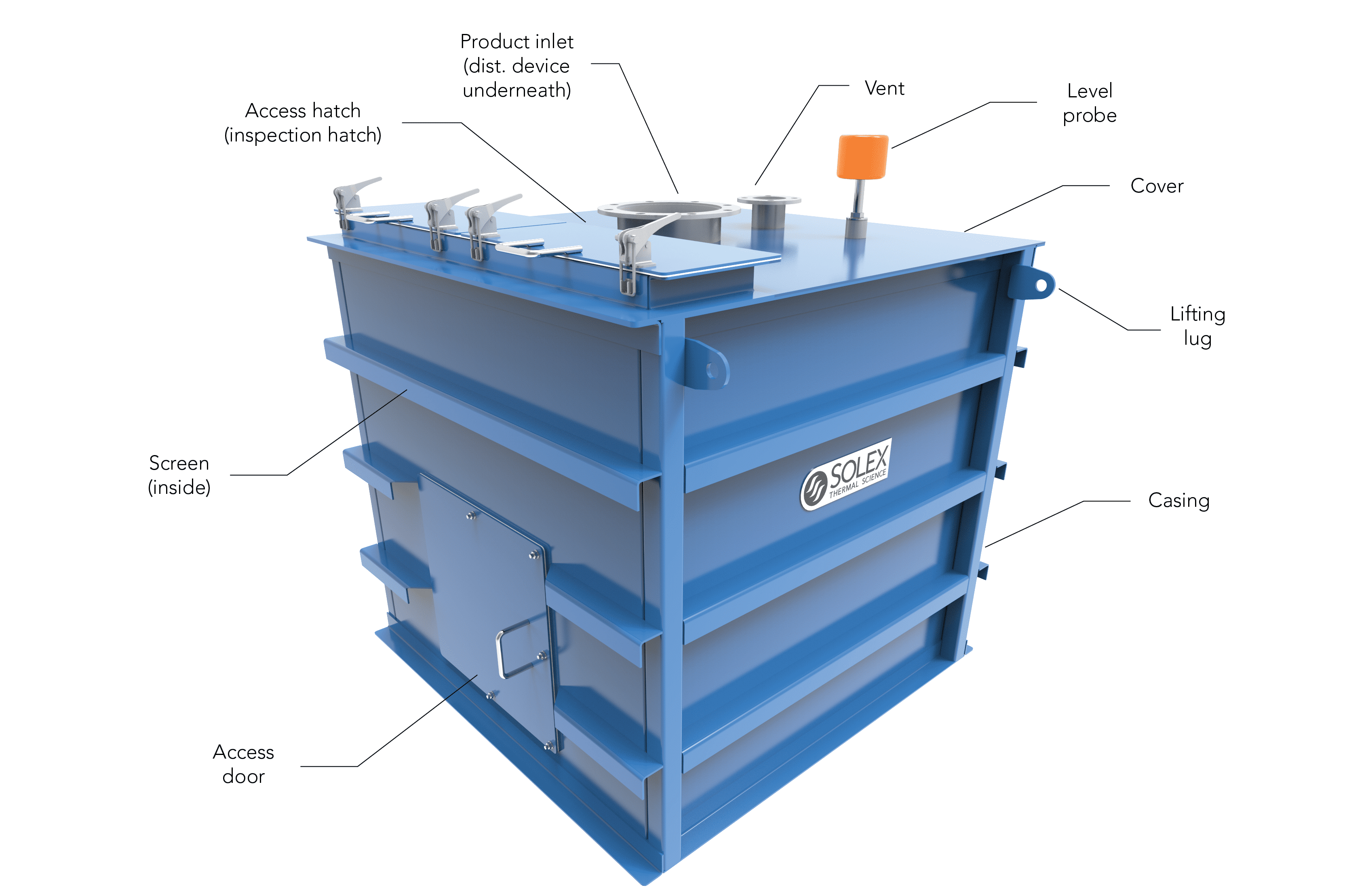

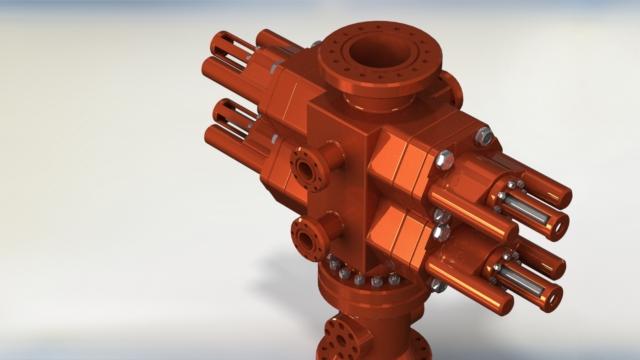

Modular Architecture

Component-based design enabling remote replacement of wear parts

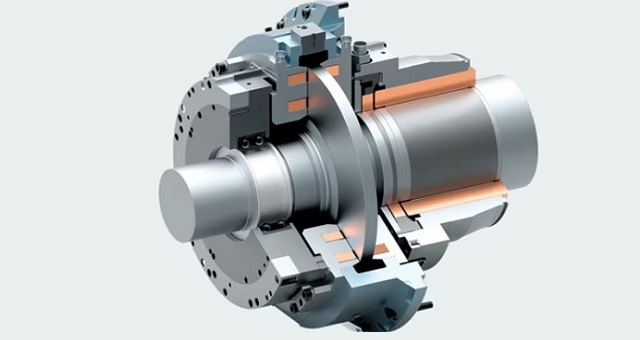

Double Containment

Redundant shielding layers ensuring >98% radiation attenuation