Nuclear Material Handling System

CSA N285.0 compliant system with 95% on-time delivery rate

Project Overview

Designed and documented a nuclear material handling system for safe transportation of radioactive components within a nuclear facility. The system required strict compliance with CSA N285.0 standards for nuclear components and ASME B31.3 for process piping.

Key Challenges

- Precision alignment requirements for radioactive material transfer

- Seismic qualification for safety-critical components

- Material selection for radiation environments

- Documentation for nuclear quality assurance

Design Process

Requirements Analysis

Collaborated with nuclear engineers to define functional requirements, safety factors, and regulatory constraints. Developed design basis memorandum documenting all requirements.

Concept Development

Created multiple concept models in SolidWorks evaluating different material handling approaches. Conducted preliminary FEA on critical components.

Detailed Design

Developed complete 3D model with proper GD&T per ANSI Y14.5. Created fabrication drawings with nuclear-grade quality requirements.

Design Review & Validation

Conducted formal design reviews with engineering and quality teams. Performed tolerance stack-up analysis for critical interfaces.

Results & Impact

Technical Specifications

Materials

- Stainless Steel 316L for radiation resistance

- High-density polyethylene for shielding components

Key Components

- Remote handling mechanisms

- Radiation shielding doors

- Precision alignment guides

Design Features

- Fail-safe interlocks

- Seismic restraints

- Contamination control surfaces

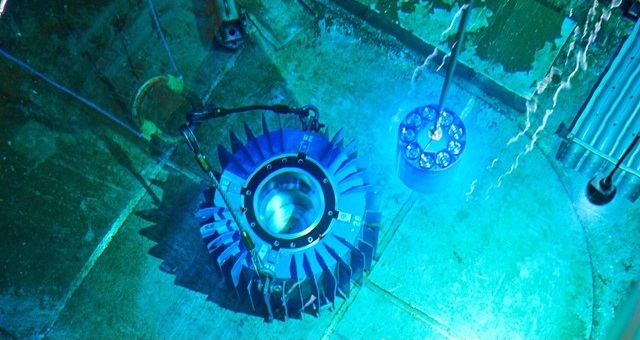

Design Visualizations

System Overview

Shielding Door Mechanism

Alignment Guide Detail