Project Overview

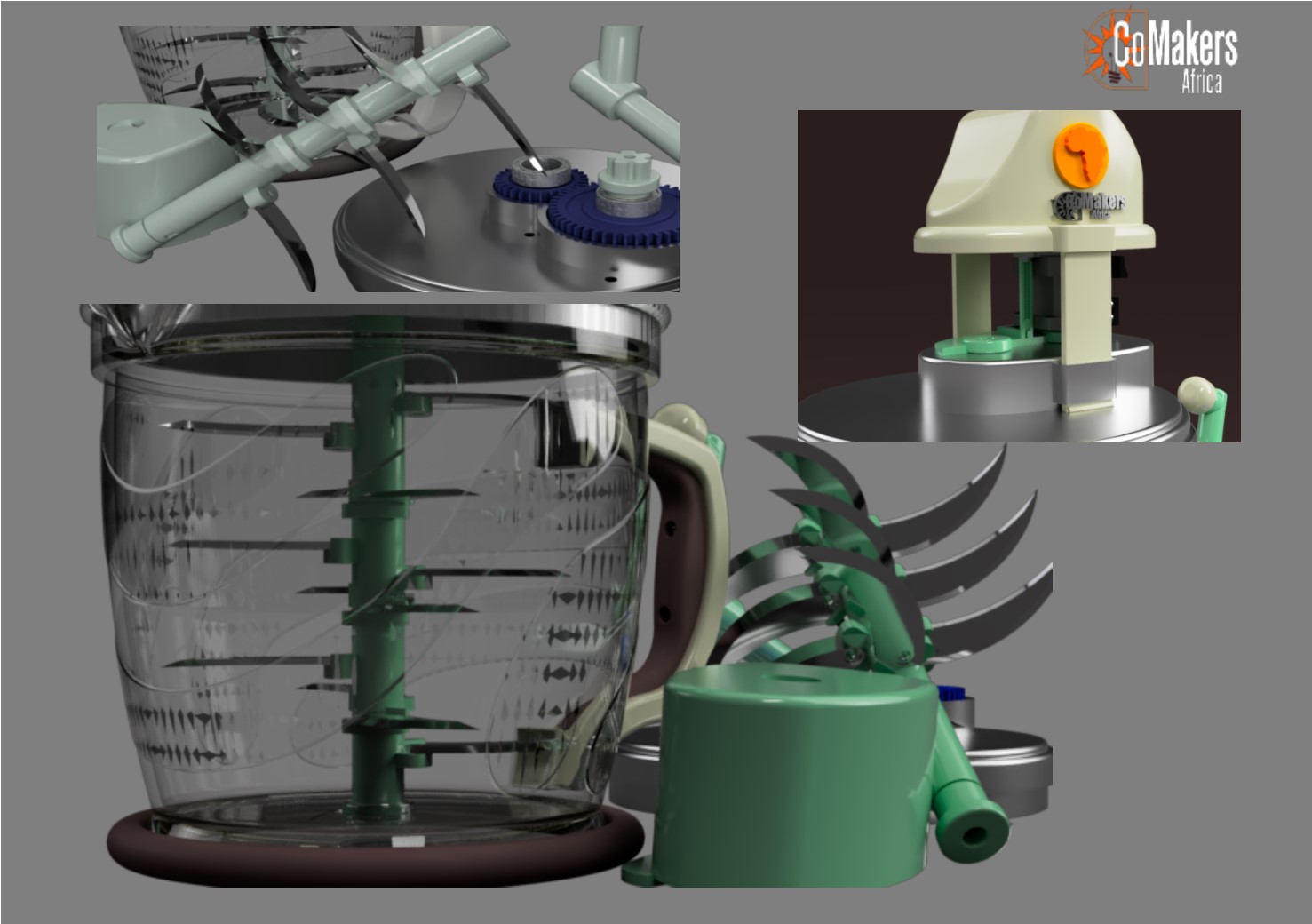

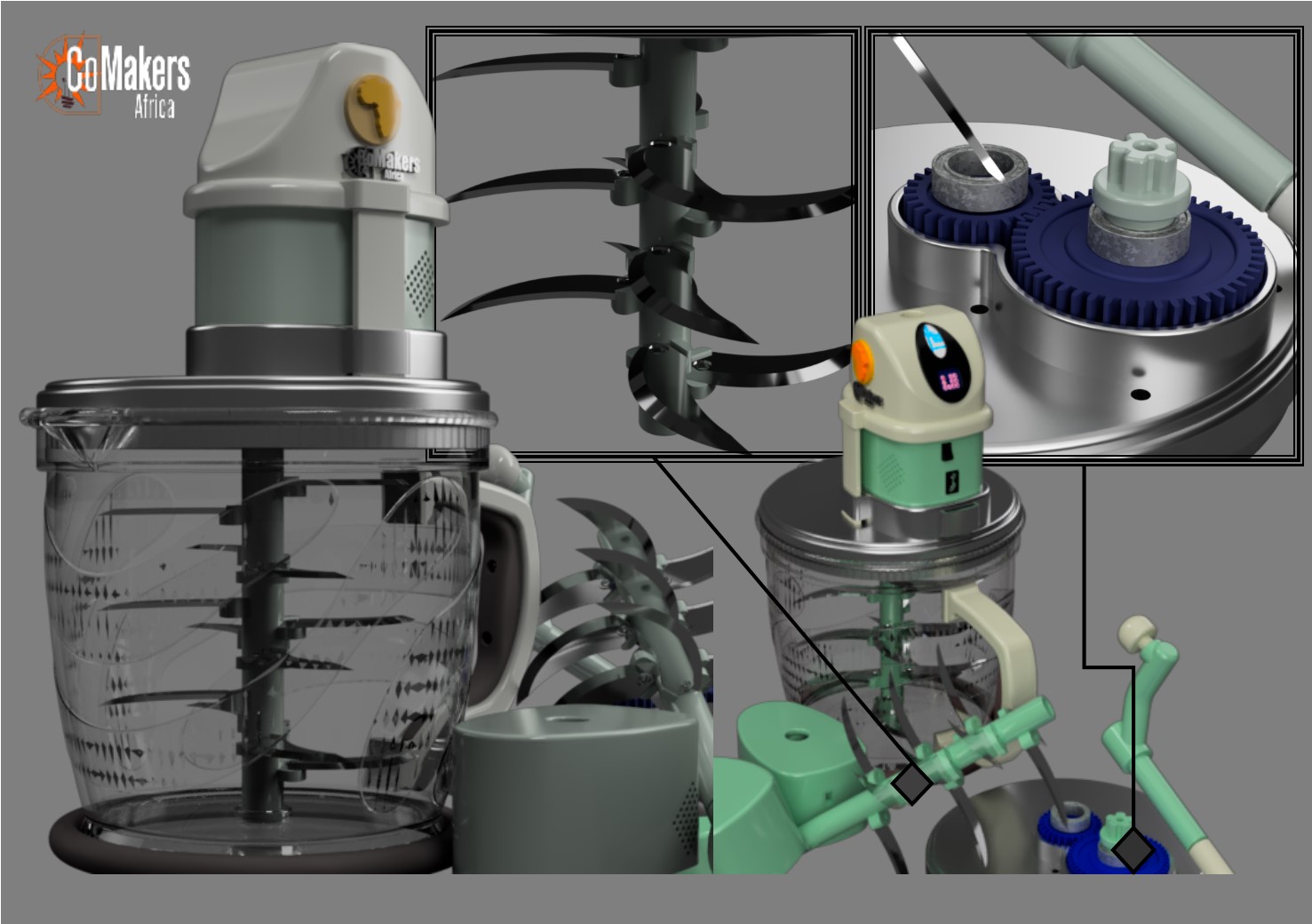

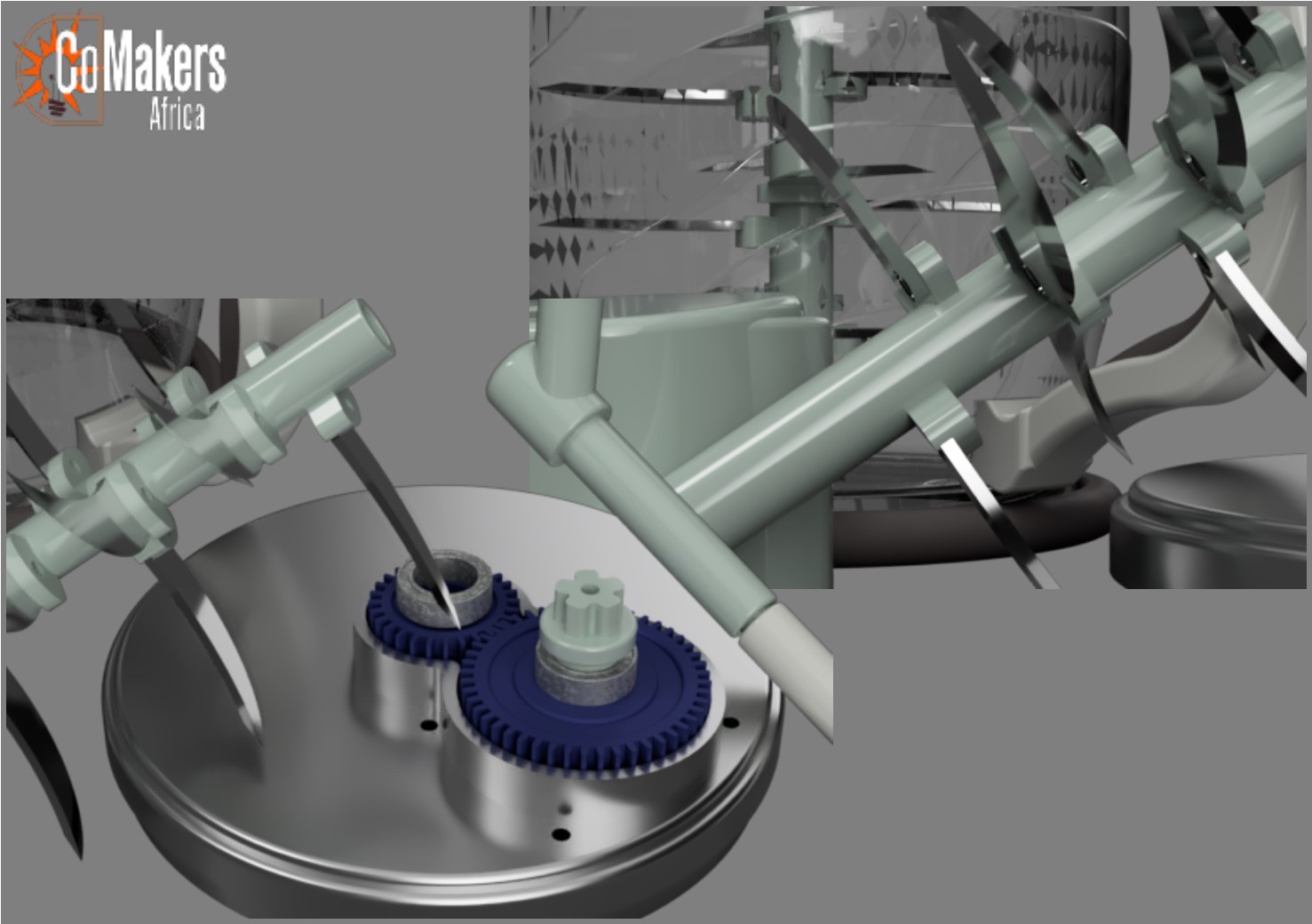

Dual-P Homer is an idea that came from observing my mother pass through the stress of grinding food ingredients on a stone or using a mortar to pound some that couldn't be ground on the stone.

There are other types of vegetable blenders and grinding machines available in the market, most of which are either manually or electrically powered. After buying my mother an electrically powered blender, the unsteady power supply in my country made it less helpful than intended. This led to the idea of Dual-P Homer - a dual powered (electrically and manually powered) blender.

Inspiration and Ideation

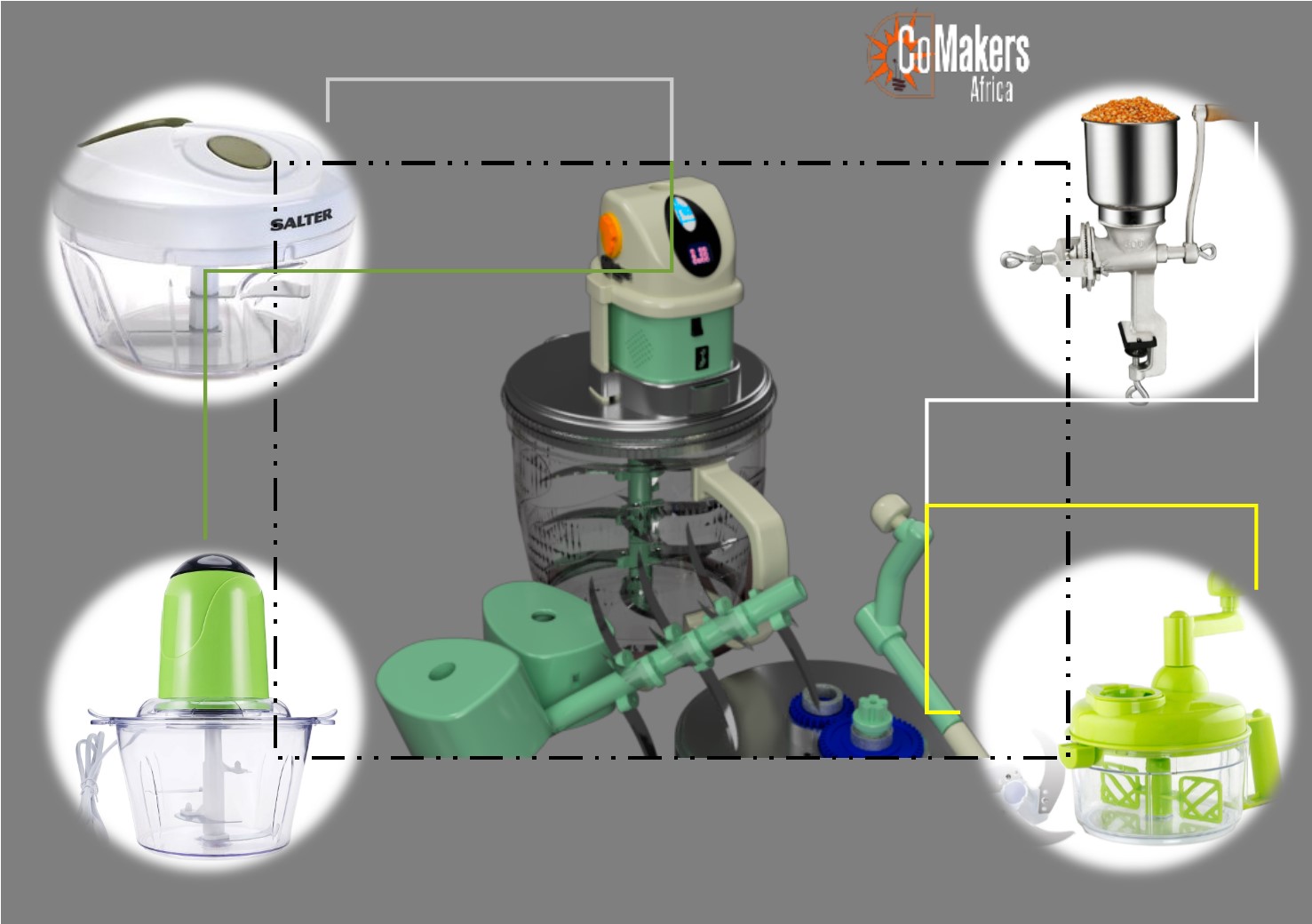

Some of my design ideas were drawn from existing machines (all credit to their original owners), with significant modifications made to ensure ruggedness and durability.

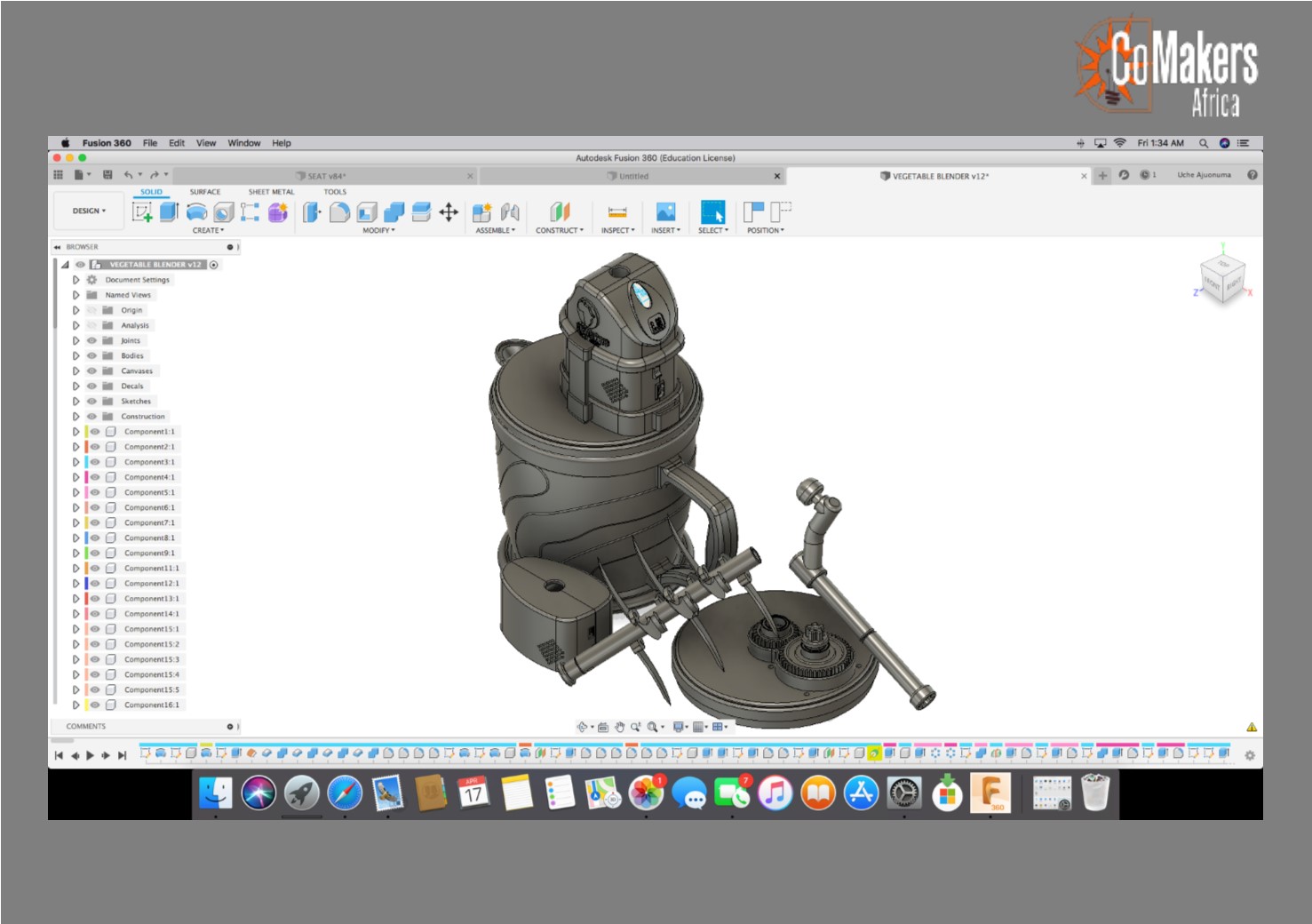

3D Modeling

While SolidWorks was my preferred modeling tool, its instability at the time led me to use Fusion 360 for this project.