Project Overview

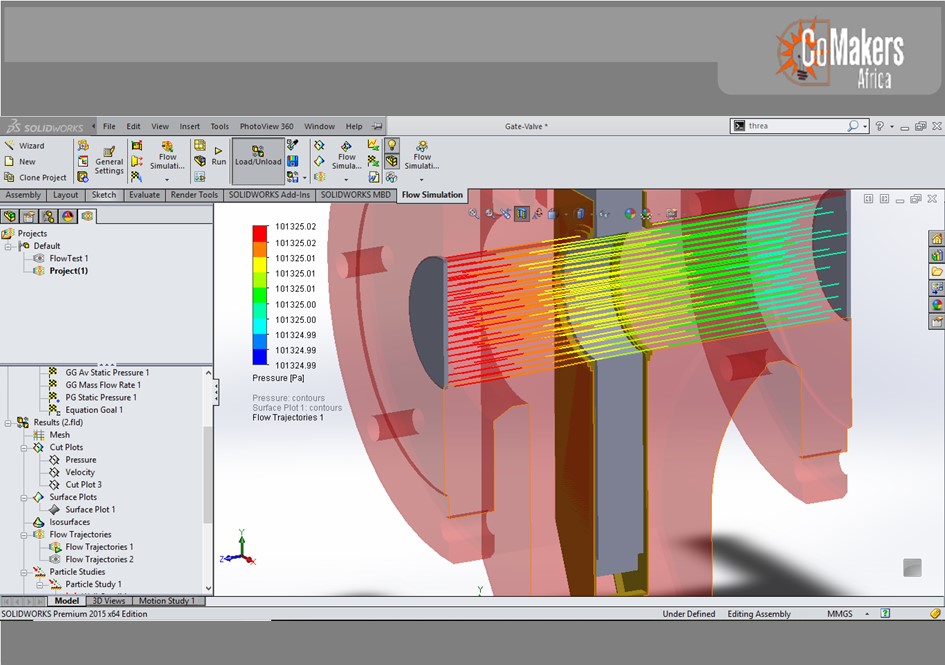

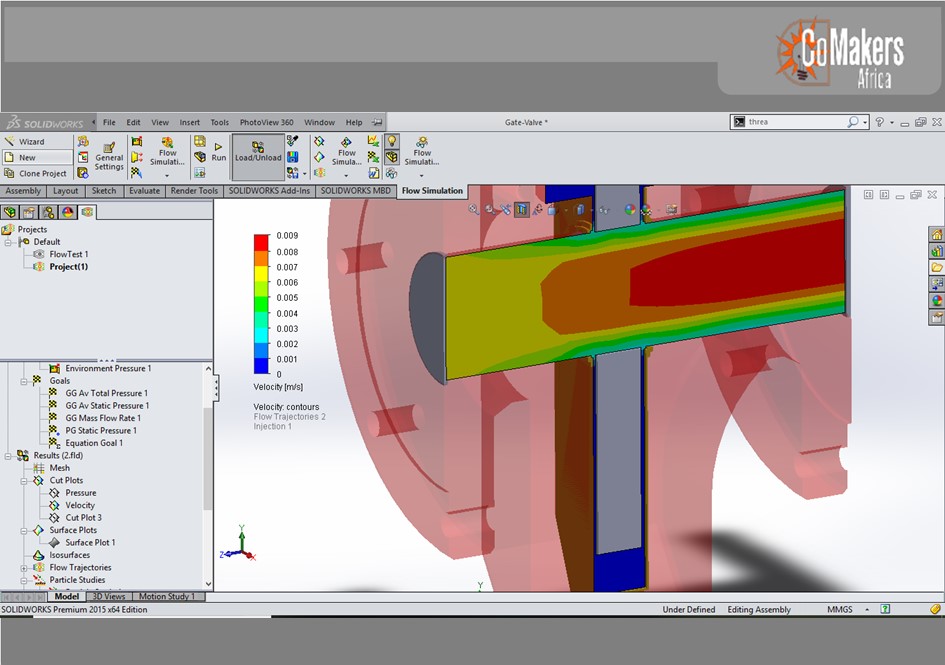

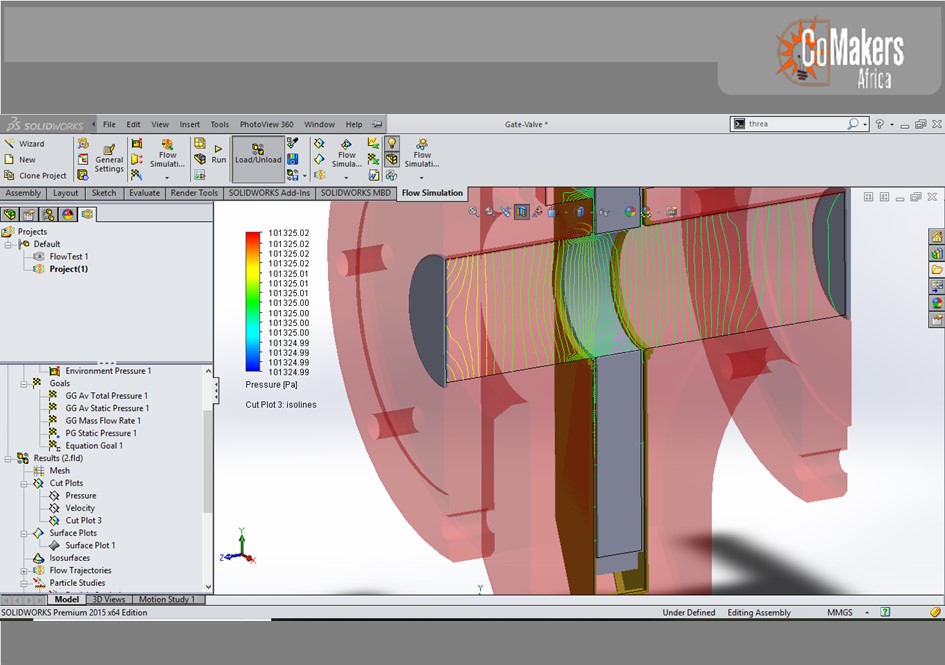

The FlowMaster Gate-Valve is a personal project developed by me in 2010 to test my Finite Element Analysis (FEA) capability in SolidWorks. It was done after I successfully designed the very batch of oil accessories for FlowMasters Ltd in Port Harcourt, Nigeria for one of its clients.

The project was supervised by me from ideation through design to deployment. At that time, majority of the testing done on the part was manual which added additional cost to the overall project. Hence, I decided to explore how accurate software-generated tests could conform with laboratory tests of the same product.

This simple trial cut down the manufacturing cost at FlowMasters Ltd by 40% and increased the delivery speed by 60%.

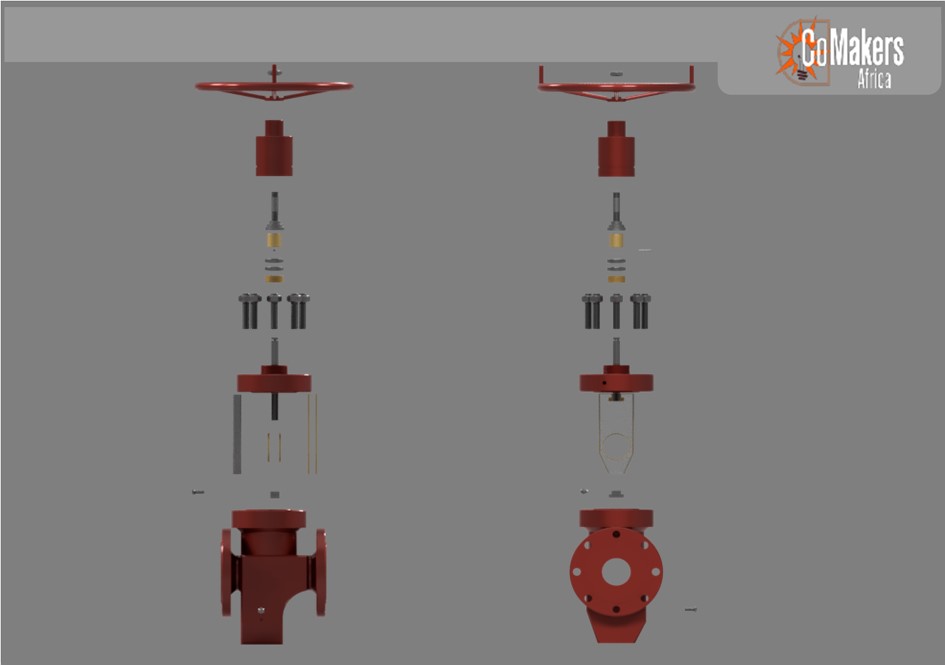

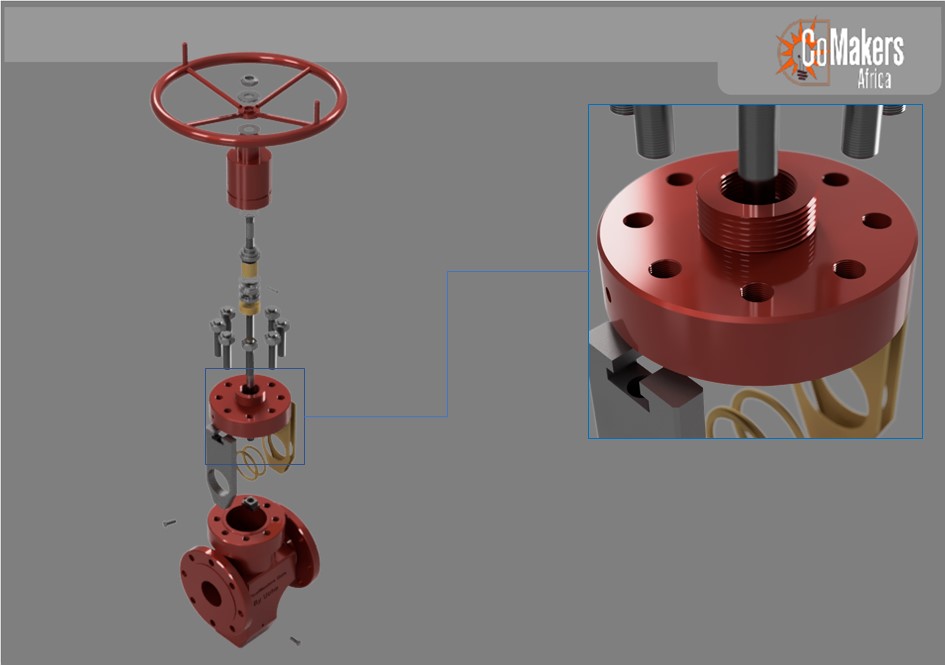

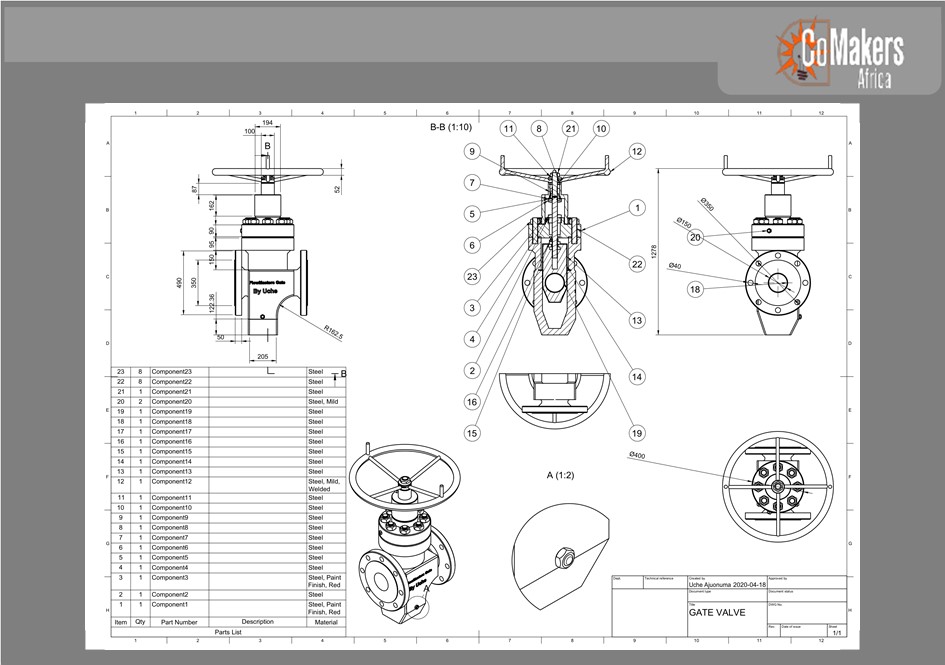

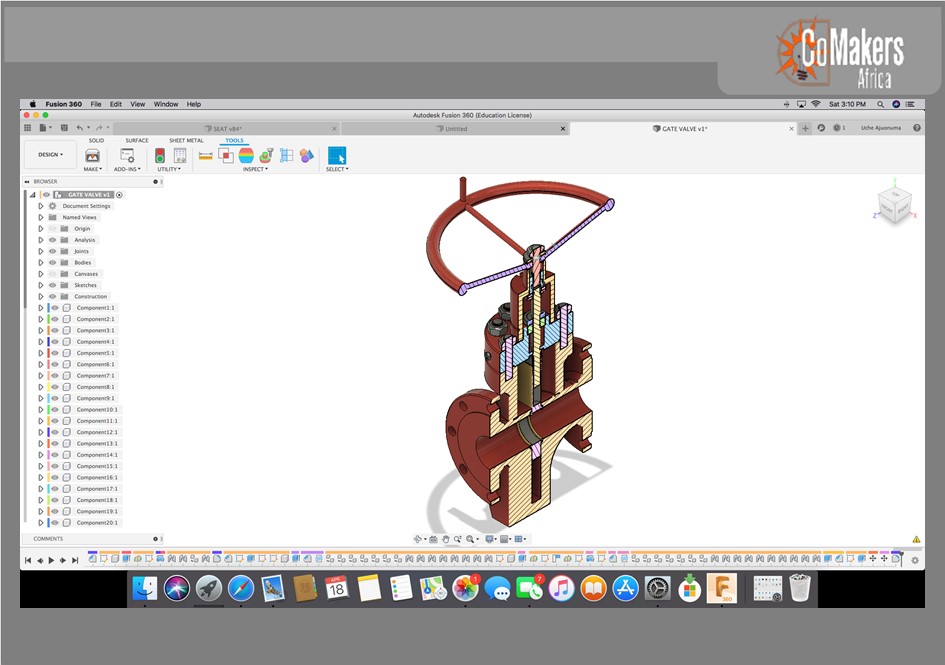

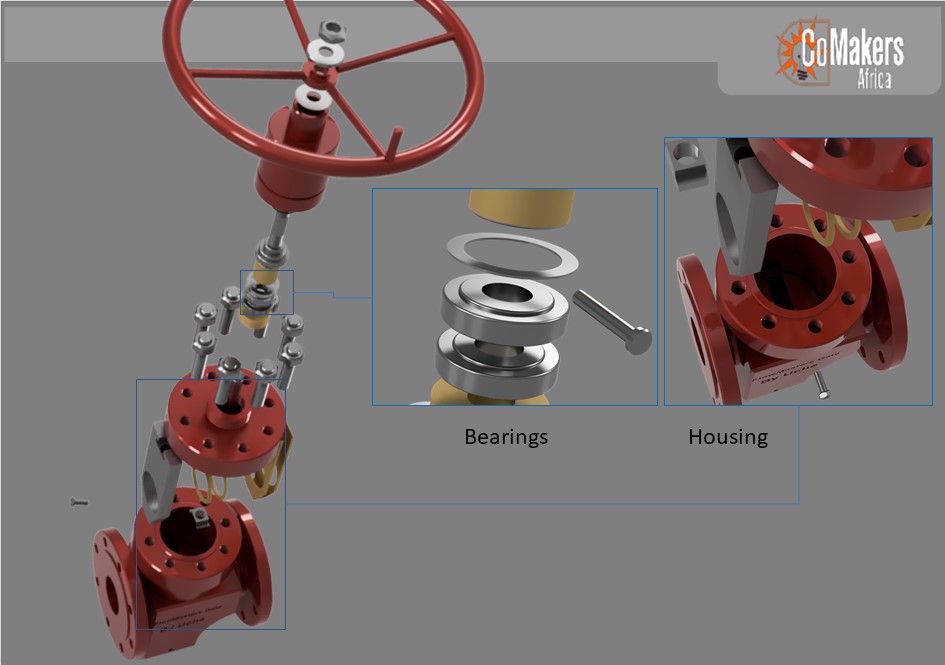

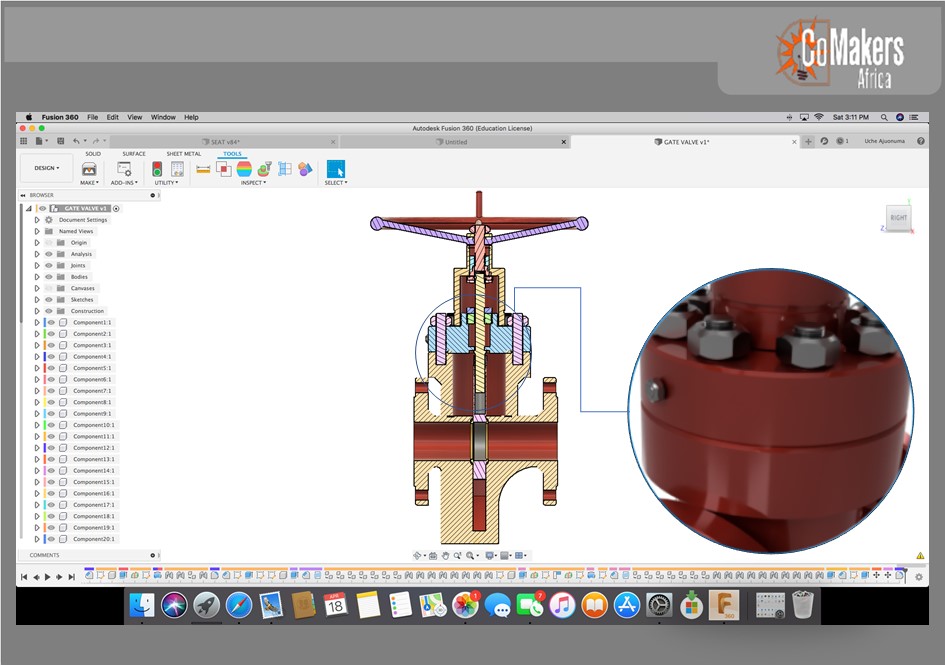

Design Process

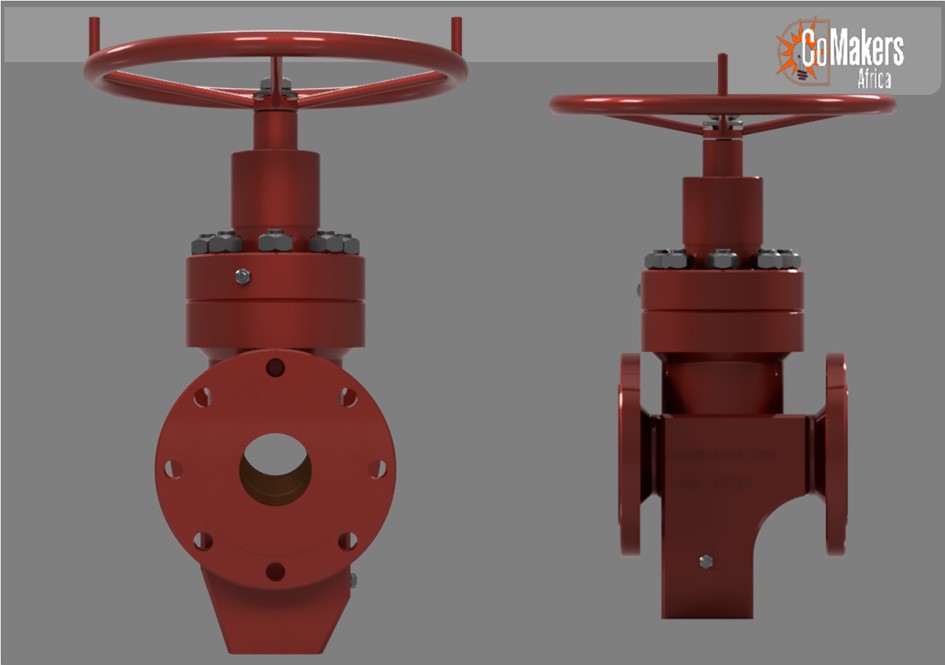

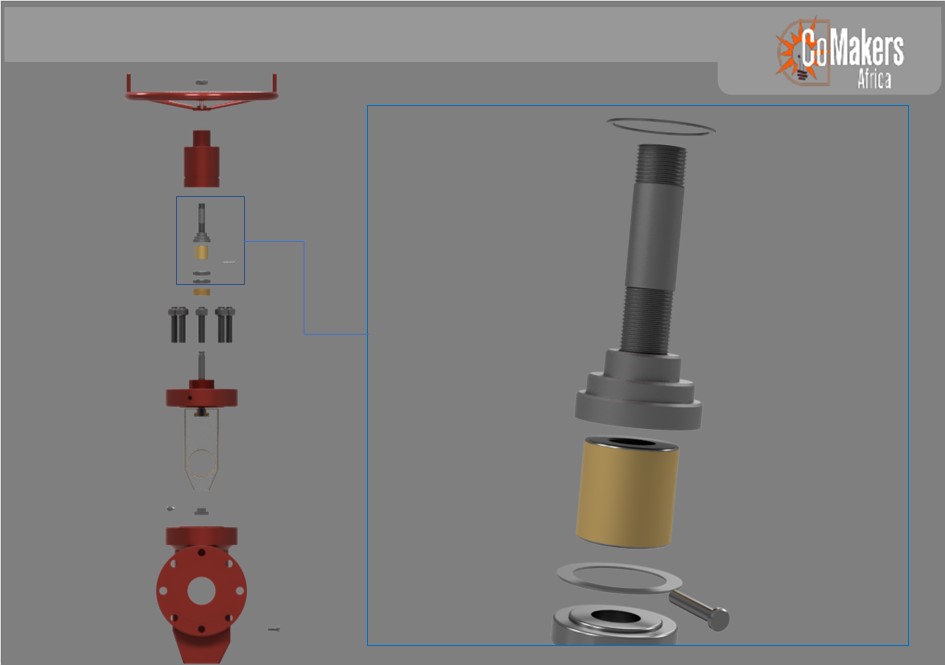

The valve was designed with several key components including the body, bonnet, gate, stem, and packing. Each component was analyzed for stress distribution under various pressure conditions using SolidWorks Simulation.