Practical GD&T Guide

Applying ASME Y14.5 Geometric Dimensioning and Tolerancing

GD&T Fundamentals

Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses a symbolic language on engineering drawings and computer-generated 3D solid models to explicitly describe nominal geometry and its allowable variation.

Form Controls

- Straightness

- Flatness

- Circularity

- Cylindricity

Orientation Controls

- Perpendicularity

- Angularity

- Parallelism

Location Controls

- Position

- Concentricity

- Symmetry

Runout Controls

- Circular Runout

- Total Runout

GD&T Symbols Quick Reference

Flatness

Controls the flatness of a surface relative to itself

Circularity

Controls roundness of circular elements

Cylindricity

Controls form of cylindrical surfaces

Perpendicularity

Controls 90° relationships between features

Angularity

Controls specific angle relationships

Parallelism

Controls parallel relationships

Position

Controls location of features

Concentricity

Controls coaxiality of features

Practical Application Examples

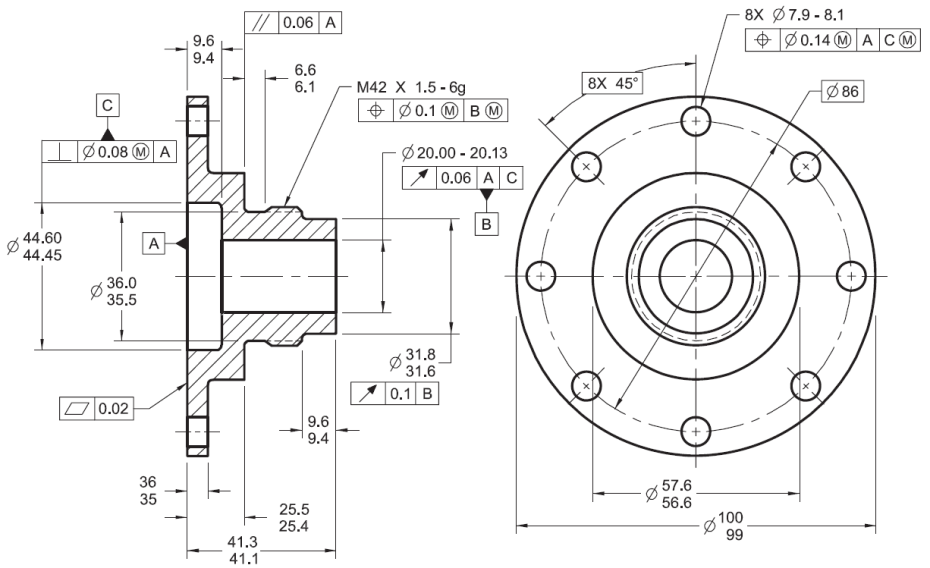

Example 1: Bracket Mounting Holes

Scenario: Eight mounting holes need to maintain precise location relative to each other and to the mounting surface.

Solution: Use position tolerance with a datum reference frame:

- Primary datum (A): Mounting surface (flatness controlled)

- Secondary datum (B): Edge for orientation

- Tertiary datum (C): Perpendicular edge for complete location

Tolerance: Position Ø0.1 relative to A|B|C

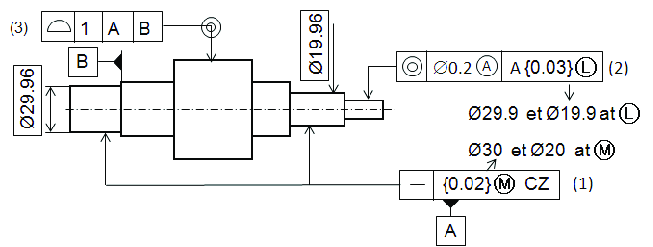

Example 2: Rotating Shaft

Scenario: Shaft must rotate smoothly in bearings with minimal vibration.

Solution: Combine multiple controls:

- Cylindricity control on bearing surfaces

- Total runout control for entire rotating surface

- Concentricity between bearing surfaces

Tolerances: Cylindricity 0.01, Total Runout 0.02 relative to axis A-B

Pro Tips for Effective GD&T

1. Start with Functional Requirements

Always base your tolerances on how the part functions in its assembly, not just manufacturing capabilities.

2. Use Datums Strategically

Select datums that match assembly interfaces and functional surfaces.

3. Consider MMC/LMC

Apply maximum material condition (MMC) or least material condition (LMC) modifiers when they provide functional benefits.

4. Avoid Over-Tolerancing

Only specify tight tolerances where absolutely necessary to control costs.

5. Combine Controls Wisely

Use form controls for individual features and location controls for feature relationships.

6. Communicate with Manufacturers

Ensure your suppliers understand your GD&T requirements and can measure them properly.