Through 50+ ASME Section VIII vessel certifications, I've identified recurring compliance challenges that cause 80% of first-review rejections. Here's how to avoid them while optimizing your design process.

Critical Pitfalls:

- Nozzle reinforcement miscalculations

- Incorrect corrosion allowance application

- Misapplied design margin formulas

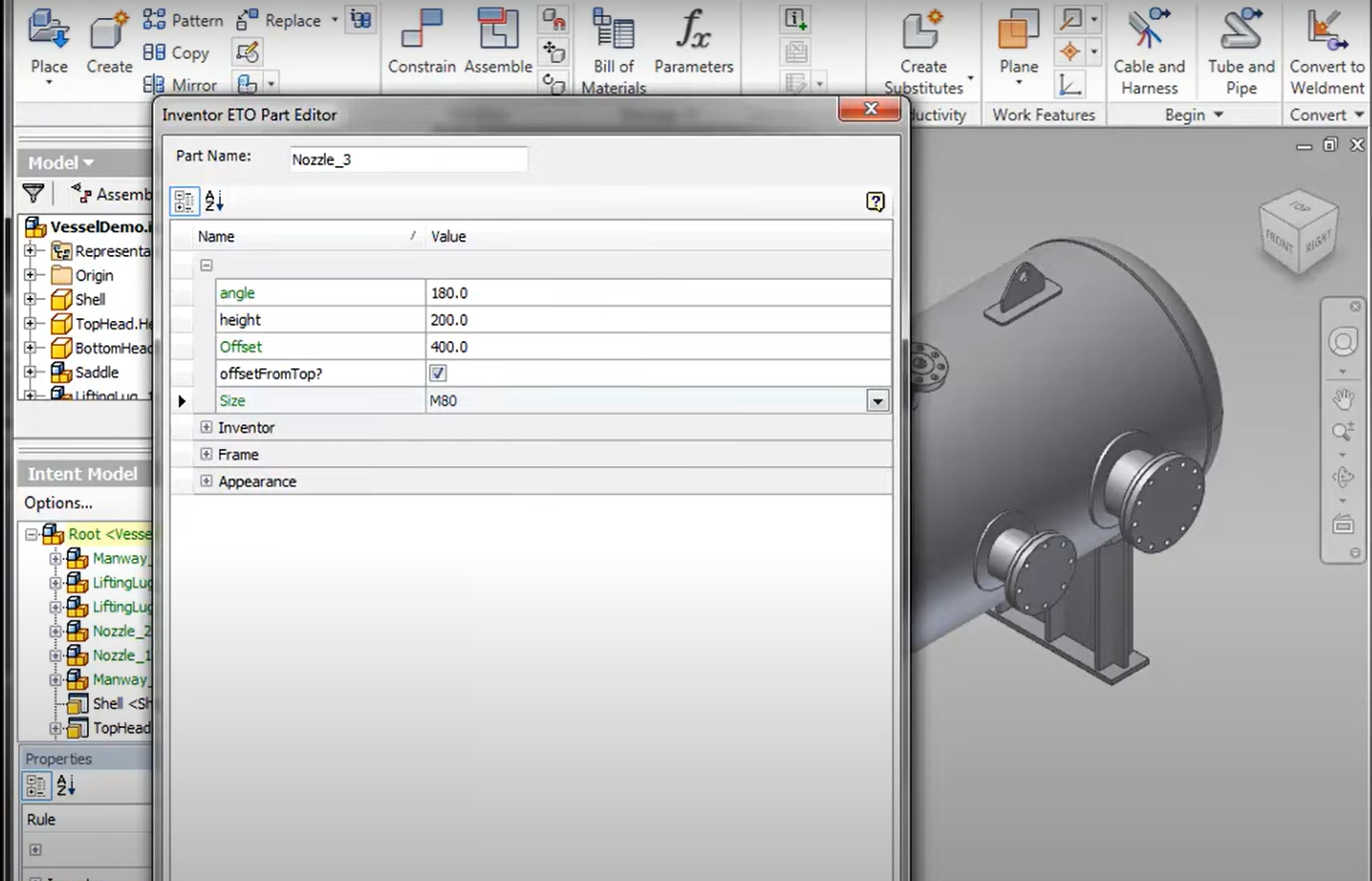

1. Nozzle Reinforcement Fundamentals

UG-37 requirements trip up even experienced designers. Key considerations:

| Requirement | Formula | Common Error |

|---|---|---|

| Minimum Reinforcement Area | A1 = d·tr | Forgetting nozzle projection |

| Available Area | A2 = 2(tn - trn)·(t) |

Misidentifying tn |

Verification Method: Always cross-check WRC-107 calculations with FEA results for nozzles > NPS 6.

2. Material Selection Traps

These material issues caused 30% of our initial rejections:

Low-Temperature Service

SA-516 Grade 70 requires fine grain practice below -29°C to pass Charpy impact tests.

Corrosion Allowance

Must be added to minimum thickness, not design thickness (UG-16(b)).

3. Documentation Requirements

ASME requires these often-overlooked documentation elements:

Compliance Workflow

Preliminary Design

Apply UG-27 thickness formulas with corrosion allowance

Detailed Verification

Validate with WRC-107/297 and FEA

Documentation

Prepare data reports per U-1/U-2 requirements

Implementing this process reduced our review cycles from 4 weeks to 5 days.